When a part looks perfect on screen but fails in production, the problem usually isn’t the concept; it’s how the design aligns with the real-world manufacturing process. That’s where design for manufacturability in injection molding (DFM) makes all the difference.

For design engineers under pressure to reduce production costs without compromising quality, optimizing for the injection molding process is a key consideration. Below, we’ll walk through how to design parts that mold cleanly, hold tight tolerances, and move through production with fewer delays, less rework, and greater efficiency.

Key Takeaways

- Build around DFM principles to improve manufacturability and part consistency

- Optimize wall thickness, draft angles, and geometry to reduce defects

- Select the right plastic material based on mechanical and thermal demands

- Cut manufacturing costs by minimizing complexity and avoiding rework

- Work with a partner early to align design and mold manufacturing from the start

Why DFM Principles Matter in Injection Molding

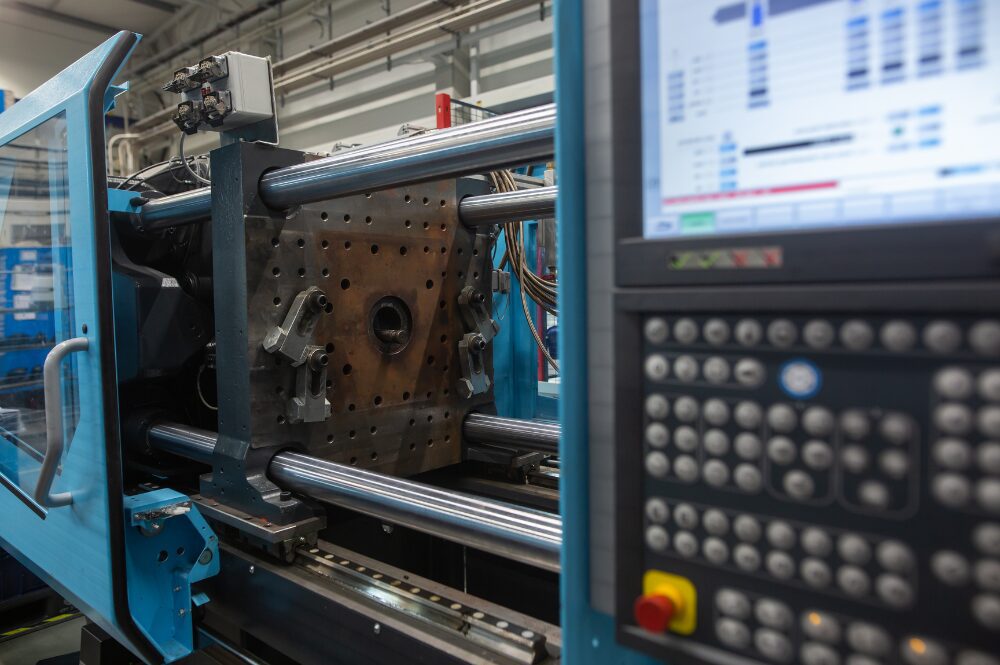

DFM in injection molding is the strategic process of designing parts that work seamlessly within the realities of tooling, flow behavior, and production.

While CAD models and simulation tools help validate initial concepts, they don’t always reflect how molten plastic will behave under injection pressure, or how a mold’s components—such as gates, ejector pins, or cooling channels—will impact production efficiency. That’s why DFM starts with a mindset of manufacturing alignment from day one.

Good DFM reduces manufacturing costs, minimizes material waste, and ensures the final product’s quality lives up to its design intent.

Mold Design Considerations That Cut Risk

When it comes to mold design, there’s little room for error. From multi cavity molds to high-volume runs, the tiniest design decision can ripple across the entire production process.

Key mold design considerations include:

- Uniform Wall Thickness: A nominal wall and consistent thickness ensure uniform material flow, reducing defects like sink marks, air traps, and weld lines. Irregular walls may cause uneven cooling or stress buildup.

- Draft Angles and Ejection: Even a small draft angle prevents friction between vertical walls and mold surfaces, which reduces wear on ejector pins and avoids drag marks.

- Gates and Parting Lines: Gate placement affects fill quality and surface finishes, while poor parting line positioning can lead to manual trimming and cosmetic issues.

- Sharp Edges and Thin Walls: Avoid sharp corners and overly thin sections. Both raise the risk of weak spots or breakage during demolding.

With over 50 years of mold manufacturing experience, PMC helps design engineers spot potential risks early and solve them before they cost you time or tooling costs.

How Part Geometry Shapes the Final Product

Part geometry does more than define the look of your part; it determines how well it fills, cools, and performs under pressure.

For example:

- Ribs and Bosses: These features add support without thickening walls. Proper spacing and sizing help maintain the part’s structural integrity.

- Undercuts: These require extra tooling or side actions, which can increase production costs. Reducing undercuts can result in significant cost savings without hurting performance.

- Snap Fits and Inserts: These functional features must account for resin flexibility and mold clearance.

Proper mechanical design not only improves function, but also helps minimize production costs. Small changes to geometry can lead to enhanced product performance and fewer post-molding operations.

Material Selection Impacts Cost and Quality

Material selection is where performance goals and cost reduction strategies meet. Different resins offer different strengths, temperature ranges, and chemical resistance. Some, like polycarbonate or acrylonitrile butadiene styrene (ABS), are commonly used in electronics manufacturing and consumer electronics for their mechanical properties and impact resistance.

Choosing the right plastic material requires understanding:

- Shrink rate and flow behavior during the molding process

- Resistance to heat, UV exposure, and abrasion

- Compatibility with tight tolerances and complex geometries

Selecting the wrong resin can compromise performance or drive up business expenses with costly tooling adjustments. That’s why PMC advises clients during early-stage design as part of a full-service production partnership.

Cost Reduction Strategies That Don’t Compromise Quality

Designing with cost reduction in mind isn’t about cutting corners. It’s about making informed business decisions that balance performance, product quality, and the realities of manufacturing requirements.

Here’s how DFM supports cost reduction efforts:

- Simplifying features reduces tooling costs and speeds up production

- Designing for fewer assemblies or secondary operations lowers labor costs

- Selecting materials based on performance and moldability prevents rework

- Avoiding unnecessary expenses tied to overengineered or untestable parts

- Leveraging repeatable designs and volume discounts in high-volume production

Together, these choices help reduce manufacturing costs, shorten lead times, and improve cash flow.

What Trusted Support Looks Like

At PMC, our support goes beyond feedback; it’s built into the way we work—with full-service clients only. That means if you bring us a complex part, you also get access to:

- High-precision CAD models and prototype testing

- Assistance with mold components, gating layouts, and tolerances

- Advice on reducing potential risks through efficient manufacturing practices

- Insights backed by decades of experience meeting industry standards across aerospace, filtration, electronics, and beyond

We’re not here to provide off-the-shelf advice; we’re here to help you build something that lasts.

Let’s Design Something That Works in the Real World

The best parts don’t just meet design intent; they meet the needs of the mold, the process, and the market. With PMC’s support, design engineers create plastic parts that hold up under pressure and perform in the field.

Our team is ready to help you align your designs with manufacturing from day one. Contact us to start your next build on the right foundation.

FAQs

What’s the benefit of DFM for injection molding?

DFM for injection molding improves part quality, reduces risk, and lowers cost by aligning design choices with real-world mold and process constraints.

How can I reduce production costs with better part design?

Simplify features, maintain consistent wall thickness, and avoid unnecessary inserts or undercuts. These changes reduce tooling complexity and save costs over time.

Why is resin choice important for tight tolerances?

Different plastics shrink and flow differently; poor choices can lead to warping or missed specs. We help identify the right material based on your part’s function and form.

Does PMC provide standalone design consulting?

No. Our design process support is integrated into full-service manufacturing. If you’re seeking a partner for end-to-end production, we’d be glad to help.

How early should I engage a manufacturer like PMC?

The earlier, the better. We can catch design issues, assist with materials selection, and reduce tooling costs before production begins.